Leather

Getting Started With "Leather Craft" for Bag Making

Below is some useful information if you are GETTING STARTED with LeatherCraft for bag-making. I'm new to leather and still getting started myself; so here is some info that helped me to get the journey started.

Leather Thickness & Cuts

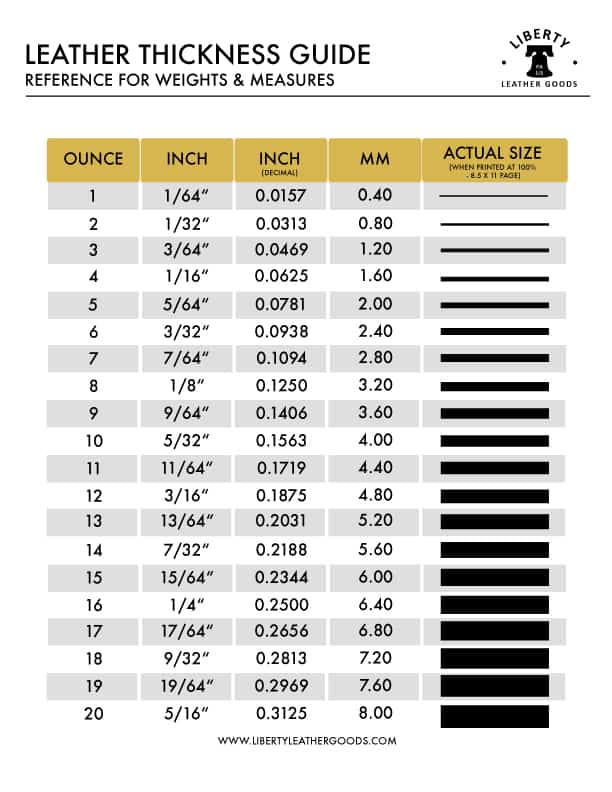

Leather thickness is measured in "ounces." Below is a link to helpful resources from LibertyLeatherGoods.com that translates this into practical terms, along with some other useful info -

General Leather Craft: https://www.libertyleathergoods.com/category/leather-craft-posts/

Leather Thickness (Below):

Leather Thickness Guide PDF

Leather Parts Guide

Tools & Supplies

Below are some LeatherCraft sellers for tools and supplies:

- BuckleGuy - https://www.buckleguy.com

- Cutex Sewing (Osborne Tools) - https://www.cutexsewingsupplies.com

- District Leather - https://districtleathersupply.com

- Rocky Mountain - https://www.rmleathersupply.com/

- RM Leather - https://www.rmleathersupply.com

- SpringField Leather - https://www.springfieldleather.com

- Tandy - https://www.springfieldleather.com

- Leather Guy - https://theleatherguy.org

- Weaver - https://www.weaverleathersupply.com

Industrial Bonded Thread

- Sunny Sewing - https://sunny-sewing-machines.myshopify.com

- Thread Exchange - TheThreadExchange.com

Industrial Leather Needles (& Thread Compatibility)

When you ask a bag-making leather-crafter what size needle they use, you will hear "Well it depends, but I mostly use X" But this doesn't help a beginner starting out.

The most common needles used for leather bag-making are Triangular Point (TRI) and some use Diamond (DIA) for stiffer leathers. Leather needles commonly used by bag-makers from either Schmetz and Groz-Beckert are commonly paired with the thread sizes below. And these are what I've been experimenting with:

- #18 TRI: used with T70 Bonded Nylon Thread usually for thinner and more supple leathers where a smaller hole is needed

- #19 TRI: used with T70 and T90 Bonded Nylon (some use Bonded Poly in T90). T70 may be used for construction/seams and T90 for both topstitching and also construction.

- #20 TRI: used with T90 Bonded Nylon Thread for the stability required with denser leathers and thicker layers and when a larger hole can be tolerated.

I also qualify this by saying that the above is generally speaking and refers to the typical "bag-making" leather-crafter because most bag-makers tend to primarily sew with finer and more supple-temper "chrome-tanned" leathers. Whereas general leather crafters also sew with thicker "veg-tanned" leathers to make more rustic bags, saddles, wallets, plus. For upholstery leather-crafters and shoe-makers, this is yet another category with varied needs. See this summary link below from Schmetz about needles for leather in general. But the most helpful are the descriptions about the difference between their TRI and DIA needles.

Needles For Stitching Leather & Other Materials:

https://www.schmetz.com/en/industrial-needles/needle-compass/cutting-points/

Type Needle To Look For

1541 & 1181 Class Machines - Multi-Purpose v Leather Needles

- Leather TRI: 135x16

- Non-Leather/Mulit-Purpose: 135x17

Do You Need A Skiver

In my opinion yes you really do. That is if you want to sew a regular-sized bag with structural results that will satisfy you. In the meantime you can use the following hand-skiving tools on smaller items, if you have the patience.

- Tandy Hand "Super Skiver" - ($10 for tool plus constant cost of blades) - works for smaller items with patience.

- Dremel Tool w/Sanding Bands ($40-$90 for Tool plus cost of bands) - makes a mess but it works if you are patient.

- Leather Skiving/Pairing Splitters ($70-$120) - if the leather is soft it easily can stretch as you pull it through/across the blade

My skiving machine is a THOR RET801, which I purchased from Sunny Sewing. Sunny was able to cut my table to a smaller custom size, add wheels, and expand the size of the waste hole underneath. I made the canvas waste bag, which is attached to the underside of my machine using tool-magnet bars from Harbor Freight (so I can easily remove the bag and the waste).

Hole Punches - Rotary Punch & Circular Hand Drive Punches

For punching holes into leather for Rivets, the most common size hole is 2.5mm. Sometimes I also like to use the smaller 2mm one for Rivets that are 8mm or less so I get a tight fit or to start the hole and t hen make sure it is straight before I widen it with the 2.5 punch.. While you can get a press die for your Rivet press to make holes, I find this method the least precise because it can be hard to see under the press and get your hole straight. Plus the dies for the press machine are expensive. I much prefer to punch holes by hand and use either a Hand Rotary tool or a simple manual circular punch drive with a mallet.

Rotary Hand Punch

- Tandy Leather - Craftool Pro Rotary Leather Punch 3230-00 (around $50)

- Herm Sprenger - Professional Handhel Pro Tool

Manual Circular/Round Punch Drives

- KSBladePunch.com - Single holes punches are available at RM Leather Supply or direct from KSBlade Korea (These are quite expensive at $20-$22each, but are the absolute best)

- Tandy.com Craftool Round Drive Punch ($7-10/each)

Mallet

- My preferred mallet is a rawhide mallet They have the least bounce when striking and are kind to your tools. Garland makes a good one at a good price point.

- My second favorite is a Poly-Head mallet Bounce is not too bad and they are less expensive than Rawhide.

Whichever you choose make sure it is at least 1 1/2 lbs (18 oz). Anything less in weight does not do the job effectively and you need to make multiple strikes which can cause issues.

Rivets

Not all rivets are created equal! If you are using rivets for vinyl or cotton, you can buy your "average" rivet. But if you are using a rivet in leather, you want one made out of a strong durable metal that isn't too soft. (Soft rivets dent more easily and may not be as durable when set into "dense " fiberous material such as leather. Also while you may be used to buying rivets by "Cap" size, when using them for leather you should pay attention to the post height. You may need taller post heights depending on the leather you are using.